The season was in deep winter but there still was a brilliant springair in South China, with beautiful flowers everywhere.

Under the courage enlightened by the 18th CPC National Congress, the overhauling team of Nanjing Nangang Power Equipment and Installation Co., Ltd. was in charge of the work of major overhauling the No.7 PG9171E turbine and reconstructing its DLN combustion system, which was started on Dec. 15, 2012, and with the common endeavors of all members of the overhauling team, and the close cooperation from the leaders and engineering staffs of Nantian Power Co., Ltd., as well as the GE field engineering personnel taking part in the DLN reconstruction, the project was successfully completed on Jan. 29, 2013. Due to other reasons, the turbine set was tested and adjusted after the Chinese Lunar New Year, and on Feb. 23, 2013, the work of testing and adjusting the turbine set was finished and the equipment was put into normal service.

Major overhauling items in the project of turbine overhaul and DLN combustion system reconstruction are as follows:

1. Inspect fuel nozzles and replace all the nozzles;

2.Inspect the combustion parts such as crossfire tubes, combustion liners, and transition pieces, replace 14 new DLN combustion liners, and replace all crossfire tubes and their retention inserted plates;

3. Inspect the compressor rotors and stators;

4. Replace the turbine¡¯s first stage nozzles. Inspect the 2nd and 3rd stage nozzles;

5. Inspect the turbine¡¯s 1st, 2nd and 3rd stage rotors, and replace the 1ststage rotors;

6. Inspect the turbine¡¯s 1st, 2nd and 3rdstage shrouds. Replace the 1st stage shrouds.

7. Measure the clearance between rotors and stators;

8. Inspect the root adjustable gaskets in compressor¡¯s 1-17th stage stators, EGV1 and EGV2, and repair the abrasion galling on compressor stator top;

9. Inspect lube system parts and replace the cartridge;

10. Dismantle and inspect auxiliary gear box;

11. Dismantle and inspect the motors of cooling water pumps;

12. Inspect the air inlet system;

13. Inspect cooling seal air system;

14. Inspect and measure clearance and angles in IGVs. Calibrate the local IGVs¡¯ angle data with the data shown on MARK-VI panel;

15. Mend air leakage in exhaust frame, and inspect frame wall and flexible seals after air exhaust;

16. Deal with existing defects in the turbine set;

17. Maintain turbine control panel MARK VI;

18. Inspect disposable parts in turbine set;

19. Calibrate and correct all pressure meters and switches;

20. Calibrate all Bently vibration sensors and replace the defected ones.

After the project of major overhauling and DLNcombustion reconstruction, the turbine set was successfully started up one time. In normal operation the equipment was in normal service.

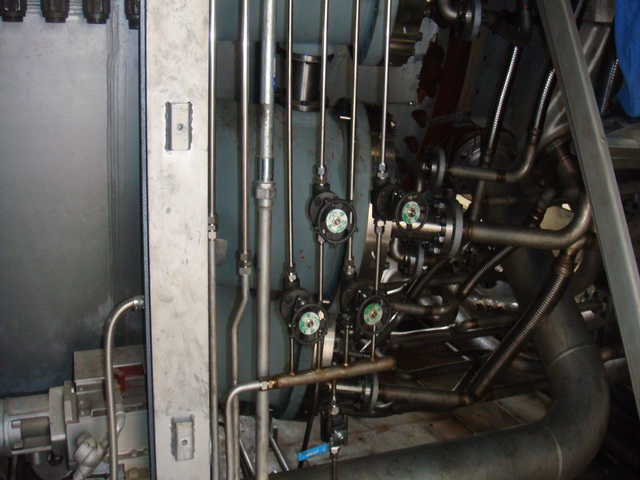

The overhauling project features with enormous items, severe requirements and complicated work load. Beside the systematic inspection on exhaust, combustion and turbine parts on the basis of overhauling instructions, the combustion system is reconstructed into DLN combustion, which is somewhat different with other projects of the same sort ever undergone at other power plants, for example, to install one more purging tube onto the new flame sensors. During installation of the purging tube, in order to make the user be more convenient in operation, the positions of the tube¡¯s operation pumps were settled more reasonably without affecting the tube¡¯s usage effect.

In the major overhauling project, for assisting the DLN reconstruction, five stages of extraction tubes in air compressor were replaced. The outlet one-way pumps in exhaust ventilator tubes of the lube system were dismantled, only the inlet one-way pumps being saved. On the needs of the client, we also added draining pumps at the bottom of the lower exhaust frame in the compressor¡¯s 5th and 11th stage.

Our rule to every member of our team is: always and similarly performing well in every project, and improving our service through endeavors, so as to make the clients satisfy and accept our work.

The No.7 Turbine Overhauling Site in Shenzhen Nantian Power Plant

The Added Purging Tubes for Flame Sensors

Hoist Rotors during Overhaul for the No.7 Turbine in Shenzhen Nantian Power Plant

The No.7 Turbine¡¯s New DLN Exhaust Crossfire Tube

Photographer: Hu Zhixing