Good day, dear leaders.

Now we¡¯re pleased to report you on the turbine installation field construction updates:

I. Under the current circumstance, the possibly handled mechanical services for 6FA turbine had been finished. The turbine set oil cycle piping was completed, and the oil cycling in lube pips can be put into force as long as the 380V power transmits into the control cell (after completion of inverse power transition in the power plant). Electrically, the cable laying inside the turbine enclosure was completely finished, and the cable wiring in the enclosure has been finished by 80% or so. Currently the 6FA turbine outer cable laying is under progress, tried to finish the work by the end of this month. After finishing cable laying, all turbine set wiring work will be maneuvered immediately.

II. Except a part of piping (the firefighting pipes and meter pipes in major) is not finished, the rest mechanical services and installation has been completed, saving the oil cycling work in turbine set lube piping to be done later. The electrical constructions mainly include the production and installation of the cable sleeves, as well as cable laying and wiring inside and outside the turbine set.

III. After the above work, if conditions are allowed, adjustment of 6FA turbine and H25 turbine will be executed. At present the digestion of adjusting files for 6FA turbine and H25 turbine is underway while the outline for field adjusting is in progress of editing.

Our company leaders¡¯ predictive strategy decision promotes us the experiences of working on various types of turbine sets, which are tremendous challenges but meanwhile the excellent study chances on the field installation. Although the total design layouts and output types (especially H25) between 6FA and H25 turbines are completely different from that we had installed and adjusted in the past, benefited from the setup experiences on ever installed GE turbines and our company¡¯s long time severe requirements on field construction quality and safety, we can smoothly execute the installation for the two turbine sets. By serious work attitude, instructed working methods, perfect construction teams and teamwork spirit, we have won trust and admiration from the owner and TA, and especially the TA for Hitachi H25 turbine is much interested in our company, having a hope of further exchanges with us in future (Hitachi will sell 2 more H25 turbine sets in China).

Attachment: field photos

Best wishes,

Anji Project Dept., Nanjing Nangang Power and Installation Co., Ltd.

Apr. 25, 2013

Inside the 6FA turbine set workshop

6FA Lube and NG modules

6FA control cell in position

6FA outer cable laying

6FA outer cable laying

H25 turbine body

H25 turbine body

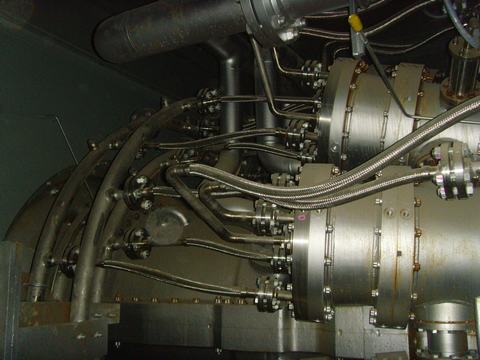

H25 combustion system

H25 combustion system

H25 combustion piping construction

H25 combustion piping construction

H25 turbine piping construction

H25 turbine enclosure installation

H25 turbine enclosure

H25 turbine enclosure and generator

H25 generator

H25 turbine inlet bracket (total height 13-meter)

H25 turbine inlet piping (total height 16.5-meter)

H25 turbine inlet casing

H25 turbine inlet casing

H25 generator alignment

H25 combustion coupling installation

H25 generator coupling installation

H25 generator coupling installation

H25 turbine workshop and plant transformer

Plant electrical transiting and transformingequipment

Photographer: Bian Qiaozhi