In early April we went to the NandianZhongshan Gas Turbine Power Plant of Shenzhen, where it was in bright and beautifulspring air, and fresh flowers everywhere.

The renovating project of DLN combustion system for the no.3 PG9171E gas turbine in NandianZhongshan Gas Turbine Power Plant was constructed by the overhauling team of Nanjing Nangang Power and Equipment Installation Co., Ltd., and the overhauling process was started on Apr. 4, 2014. Under common endeavors from overhauling crew members of Nanjing Nangang Power and Equipment Installation Co., Ltd., and with close assistance from related leaders and engineering technicians from NandianZhongshan Power Co., Ltd., as well as GE field engineering technicians, the renovating project of DLN combustion system was successfully completed on May 19, 2014. On May 20, after executing combustion adjustment, the turbine set started normal running with full load.

The major overhauling items for the renovating project of DLN combustion system are as below:

1.Inspect the fuel nozzles, and replace all fuel nozzles;

2.Inspect the combustion parts such as crossfire tube, firing liner, transition piece etc., and replace with new crossfire tube, firing liner and flow sleeve;

3.Replace all combustion casings;

4.Renovate air compressor stage V suction tube;

5.Block the flange end of the parts dismantled from auxiliary gearbox;

6.Renovate cooling water tube of the fire detectors;

7.Add temperature measuring elements in inlet system;

8.Inspect cooling seal air system;

9.Inspect and measure related clearance and angles of the IGVs. Calibrate the locally got angles of IGV with those indicated on MARK-VI controlling panel;

10.Add pressure measuring elements in exhaust flue;

11.Deal with related defections existing in turbine set running;

12.Dismantle MARK V gas turbine controlling panel, and replace with a new MARK VIe controlling panel;

13.Inspect all disposable elements of the turbine set;

14.Calibrate and correct all newly added pressure transmitters and pressure switches;

15.Calibrate the flammable air detectors in turbine set, and replace all defected detectors.

After the renovating project of the DLN combustion system, the turbine set was successfully fired one time for the test running. The turbine set was performing normally in normal running.

The renovation is featured with enormous items and high requirement, because the DLN combustion renovation in turbine combustion system was put forward new requirements on some items. Also, in the regard of the renovating construction in the system, the DLN renovation is somewhat different with the DLN renovating projects ever executed in other power plants, to take an example, a line of purging pipe was added on the position of new fire detectors. In the arrangement of the purging pipe, for more convenient operation of turbine running by the owner, we arranged the pipe operation valves position more reasonably but not affecting the function of the piping. Temperature measuring points and humidity measuring points were added in the inlet system.

In the overhauling, the air compressor stage 5 suction pipes were renovated and renewed, in the regard of the convenient dismantlement and installation for the branch pipes in the DLN renovation. Also, a dirt drain pipe orifice was added in the purge piping of the valve station.

Our requirement to every staff is to always perform well in each project, and through our endeavors, boost our working level with no stop, so as to win clients’ satisfaction and approval on our work.

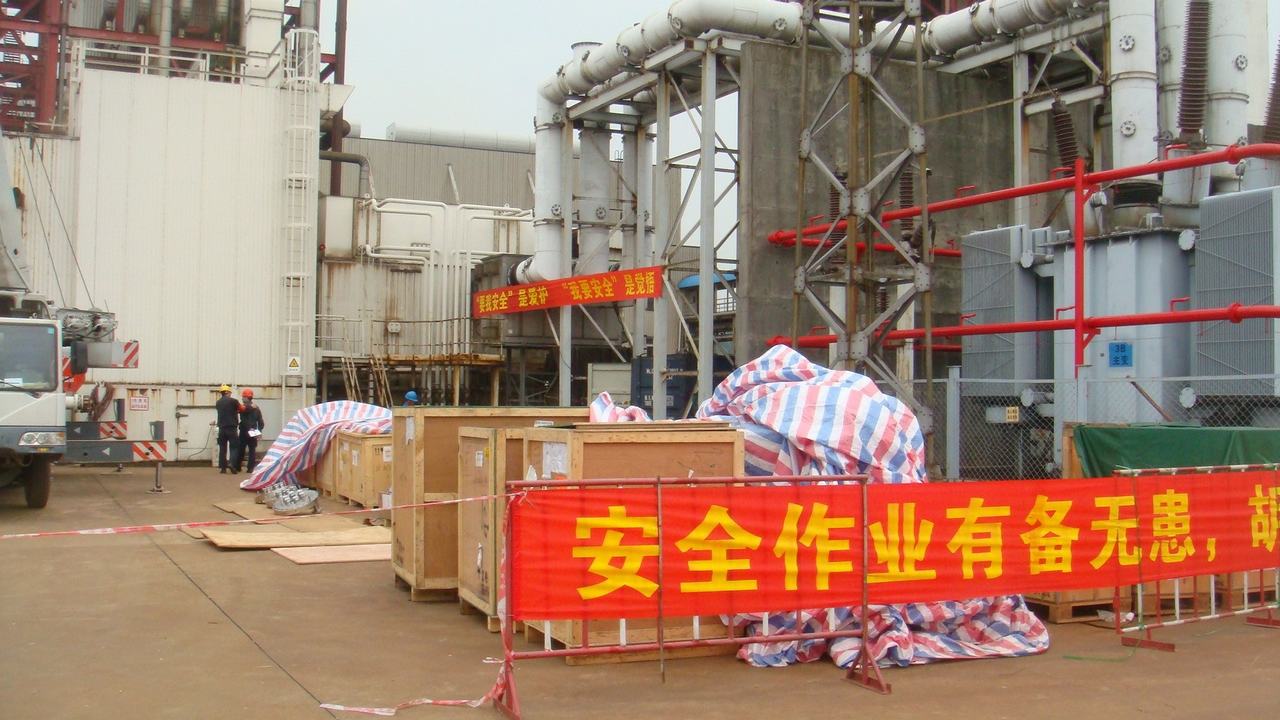

Corner of the no.3 turbine working field in power plant

Newly added fire detector purge piping

NG valve station newly installed for the no.3 gas turbine

Newly installed combustion system

The old fuel skid is dismantled

Photographer: Hu Zhixing