In March, 2014, a sudden boost of turbine set vibration happened on the operating no.2 gas turbine in Liuzhou Xinhegang Power Co., Ltd., and by inspecting the turbine after shutdown, it was found that several turbine stage III rotors fractured, most vanes had breaches, and turbine stage III nozzles and stage III shrouds were impaired more or less. Regarding the emergent situation, Xinhegang Power contacted our company, expecting us to organize construction equipment and personnel and launch an emergent overhauling on the no.2 gas turbine. In the face of the owner’s requirement, we actively commenced constructing preparation, assisting the owner to prepare spares for replacement, arranging and coordinating constructing personnel, and dealing with the mission with fastest speed.

In accordance with contract and technical agreement, the overhauling unit of Nanjing Nangang Power and Equipment Installation Co., Ltd. was in charge of the overall major overhauling for the mainframe of the gas turbine. In the overhauling process, with the comprehensive cooperation and substantial assistance from different departments of the owner, holding our service motto of Worry for the Client and Think for the Client, and with the dependable service attitude and reliable service force, we smoothly completed the mission of overhauling.

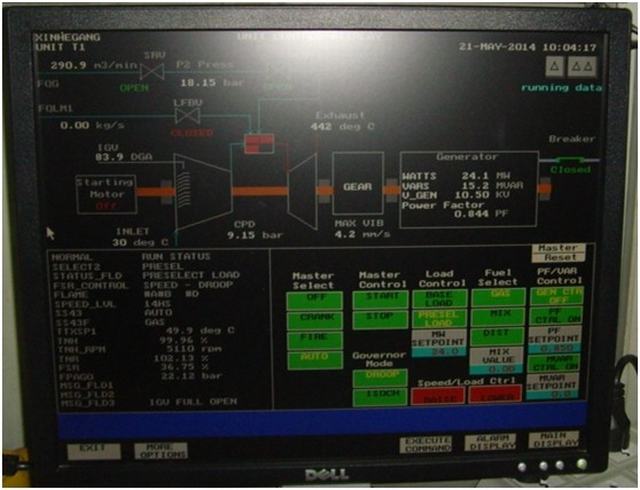

The overhaul started on Apr. 18, 2014, and the overhaul for turbine body was ended on May 21, 2014; the gas turbine set is running in good state.

Major working items completed in the overhaul:

Before opening casings, execute first check of alignment for the turbine set;

Check auxiliary coupling;

Measure rear rotors’ position before inspection

Check inlet guide vanes IGV, measure clearance, adjust and calibrate angles;

Check fuel nozzles;

Check gas fuel metallic hose;

Dismantle and check outer enclosure of combustion chamber;

Check firing liner;

Check transition pieces;

Check horn frames;

Check and clean the flow sleeve;

Check crossfire tubes and replace partial crossfire tubes;

After opening casing, measure the clearance of turbine rotors and stators;

After opening casing, check and measure the clearance of no.1 and no.2 bearings, that between thrust bearings and that between bearing air seals;

Execute dye penetrant detectionon stage I turbine nozzles;

Execute fluoroscopy penetrant detection on stage I turbine rotors;

Execute dye flaw detection on stage I shrouds;

Execute dye penetrant flaw detection on stage II turbine nozzles;

Execute fluoroscopy penetrant detection on stage II turbine rotors;

Execute dye penetrant flaw detection on stage II shrouds;

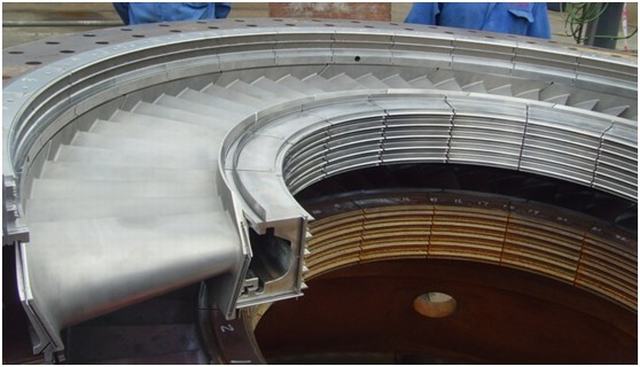

Replace with new stage III turbine nozzles;

Replace with new stage III turbine rotors;

Replace with new stage III shrouds;

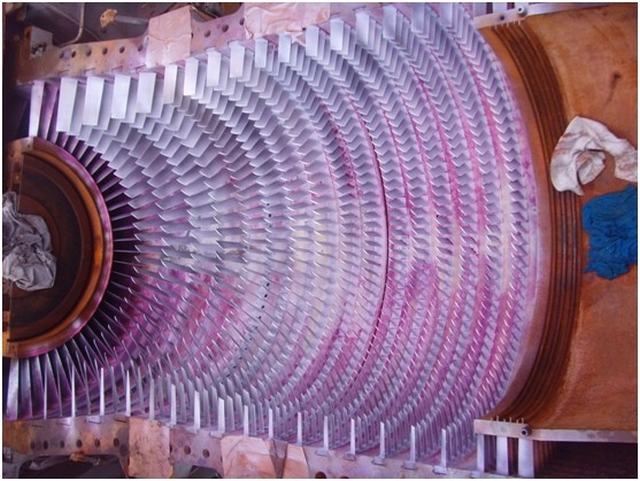

Clean air compressor rotors and stators, and execute dye penetrant flaw detection;

Checkstage II and stage III wheel space thermocouples and replace the disabled thermocouples;

Checkno.1 and no.2 bearing, and the trust bearings;

Before closing the casing, measure the clearance of air compressor rotors and stators;

Before closing the casing, measure clearance of turbine rotors and stators;

Before closing the casing, check the clearance of no.1 and no.2 bearings, that of thrust bearings and that of bearing air seal;

Check and repair cracks on exhaust casing and exhaust diffuser;

Execute alignment of gas turbine and auxiliary gearbox;

Execute alignment of gas turbine and load gearbox;

Check and install load coupling.

Severe fractures on stage III rotors

Dismantlement of cracked stage III rotors was completed, waiting for new parts to install

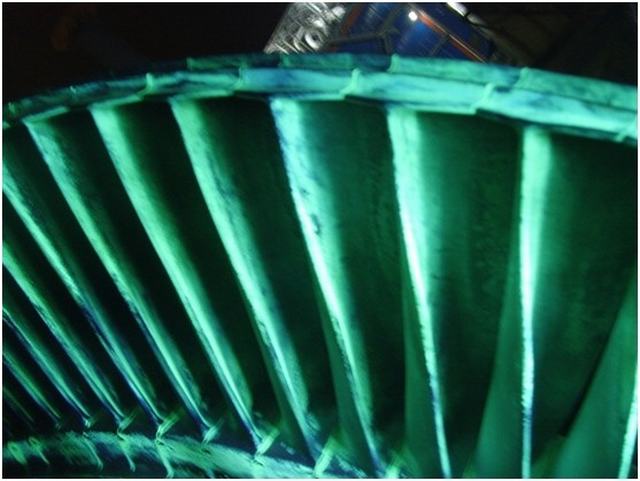

Flaw detection for rotors

Flaw detection for air compressor

Flaw detection for turbine rotors

Install new turbine stage III rotors

Install new turbine stage III nozzles and new stage III shrouds

Reinstall the rotors

Completion of reinstalling the turbine set

The turbine set runs with coke gas, with the load 24MW, and in good state

Photographer: BianQiaozhi