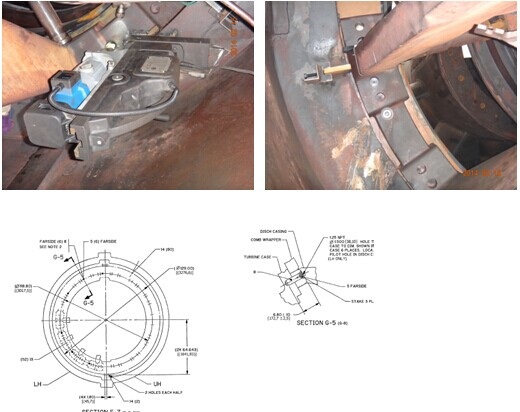

In the overhauling project for no.3 gas turbine in Nanshan Thermal Power Co., Ltd., at the moment of dismantling stage III shrouds, the slot T used to install stage III shrouds in turbine casing was found cracks, and through discussion, it was believed that the casing could not be used.

Indicated by photos:

On the spirit of hard working and arduous study on technical breakthrough, within very short period, the related personnel sent by Nangang Power put forward to two sets of schemes, returning the casing back to Nanjing Turbine & Electric Machinery (Group) Co., Ltd. or replacing it at the working field, and made comparison on advantages and disadvantages for the two schemes. The replacement of turbine casing was the first project in our country, so leaders of Nangang Power took it important, and Manager Kou and Manager Yan visited the working field and directed the process. Finally, Nanshan Thermal Power Co., Ltd. selected the onsite replacement of turbine casing (including the process of laser alignment). In order to process the onsite casing replacement, Nangang Power fabricated construction scheme and method card which were delivered to Nandian specialists and approved, so the total process of construction was strictly complied with construction scheme and method cards.

The overhauling unit of Nanjing Nangang Power and Equipment Installation Co., Ltd. completed the replacement of turbine casing (including laser alignment) for owner’s no.3 gas turbine from Jan. 8, 2014 to Mar. 2, 2014, and in the period of Jan. 15 to Feb. 10, the turbine exhaust frame was returned to Nanjing Turbine & Electric (Group) for repair and the new turbine casing was in the process of connection alignment.

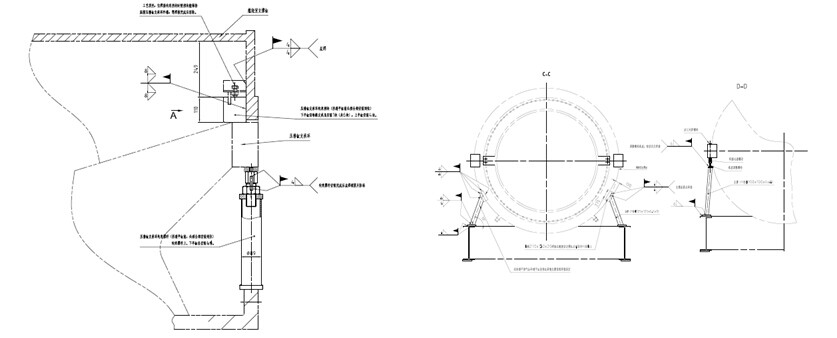

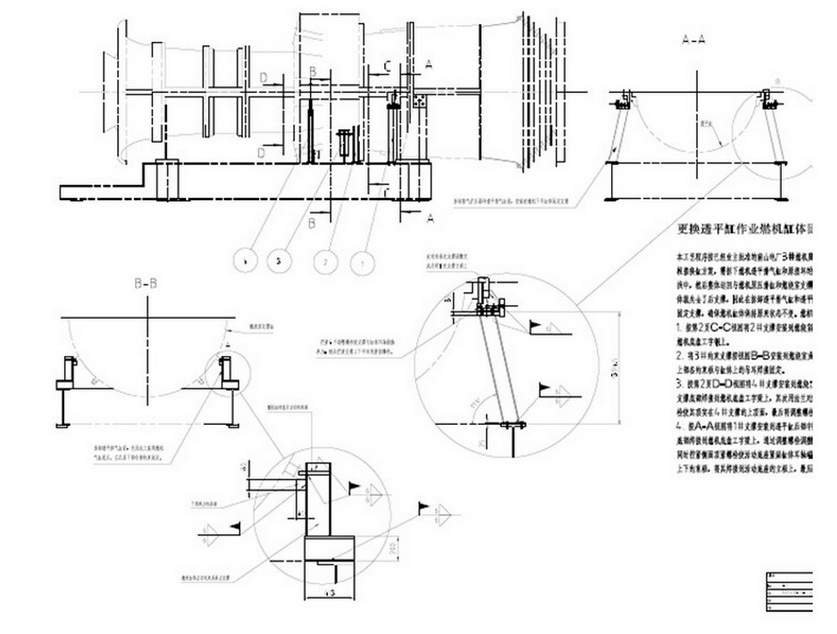

I.Before dismantlement of casing, mount and consolidate the combustion frame and turbine casing with a jack mounting the bottom, and supervise the casing deformation and displacement by a diagram. After dismantlement of turbine exhaust frame and turbine casing, ensure the combustion frame and compressor discharge casing are not deformed and displaced.

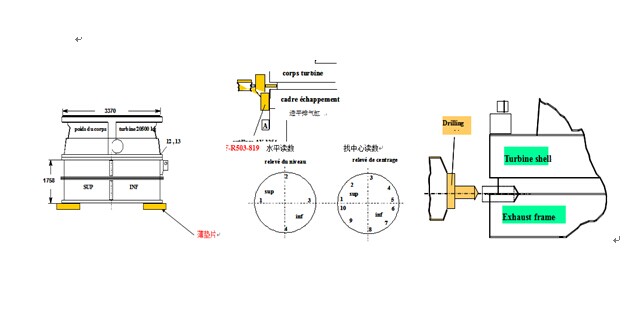

II.Return the turbine exhaust frame to the maker, aligned upright with the new turbine casing; drill and ream three axial dowels and ten radial dowels.

III.Back install the turbine exhaust frame and turbine casing, mount the casing; beside the turbine casing bottom mount and side mount in reinstallation, rough alignment and consolidation are executed for removal of casing.

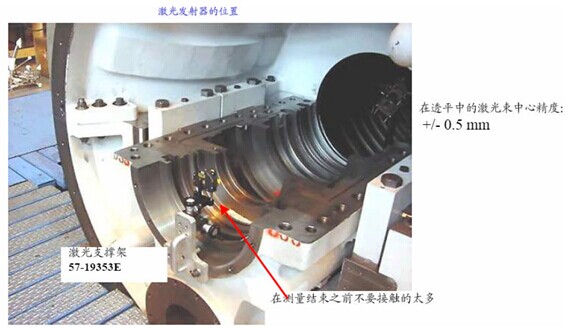

Step I: Execute laser alignment for the turbine casing:

Step II: Back install exhaust frame, execute alignment according to the dowels and orifices aligned in the maker’s plant, install three axial dowels and ten radial dowels, and mount the flange and its lift ears behind the exhaust frame; three mounts are settled.

IV.Drill and ream the vertical dowel orifices on turbine casing and air compressor discharge chamber, turning them to 6- Φ 39, and dismantle mounts to recover running state of the turbine set.

V.Laser alignment and adjustment of bearing housing

Illustration:

B1: no.1 bearing housing; Z: casing datum level; C10: compressor stage 10; C17: compressor stage 17

B2: no.2 bearing housing; T1: stage 1 nozzle mount ring; S1: stage 1 shroud; S3: stage 3 shroud; TE: turbine exhaust frame; B3: no.3 bearing housing

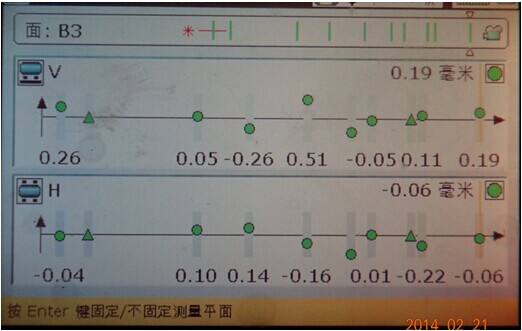

Final laser alignment data after compressing bearings (2014/2/21)

|

坐标 |

B1 |

Z |

C10 |

C17 |

B2 |

T1 |

S1 |

S3 |

TE |

B3 |

|

V(垂直) |

0.26 |

0 |

0.05 |

-0.26 |

0.51 |

-0.37 |

-0.05 |

0 |

0.11 |

0.19 |

|

H(水平) |

-0.04 |

0 |

0.10 |

0.14 |

-0.16 |

-0.38 |

0.01 |

0 |

-0.22 |

-0.06 |

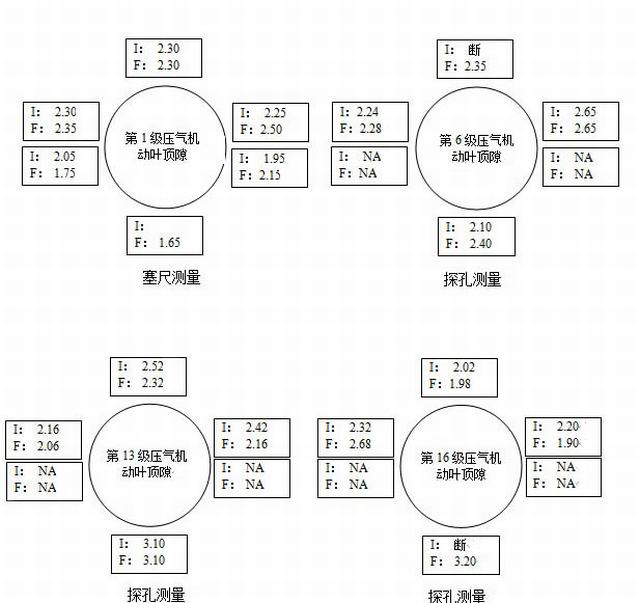

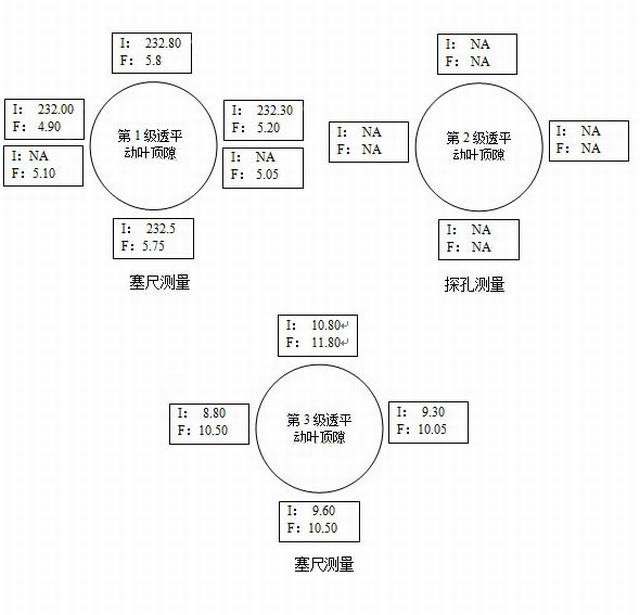

VI.Check rotor position (top clearance), check by measuring orifice and feeler gauge.

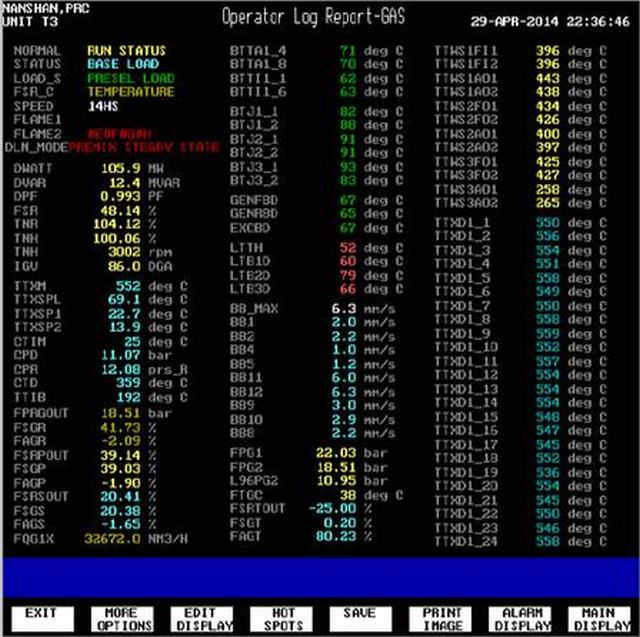

VII.Test running

On Apr. 6, the turbine set was inspected by low speed crank, no abnormal sound. On Apr. 7, high speed crank inspection and firing were executed, on Apr. 8, running with full speed zero load and partial load was executed, and on Apr. 15, running with full load was executed, so through over one month of running, by now the turbine set has been run in normal state, and all turbine parameters are normal too.